Indice

Dowelling is one of the most common and reliable ways to assemble wooden furniture. When placed correctly, beechwood dowels create a strong and lasting joint. In this guide, we’ll walk you through how dowel joinery works, which tools to use (including a dowel jig for precise drilling), and how to glue everything up for a clean and solid result. A classic and simple method, perfect for DIY lovers!

What Are Beech Dowels?

This article will discuss one of the most popular methods for assembling wooden furniture parts: using beech dowels.

So, what exactly are beech dowels?

They are simply small cylindrical pieces of beech wood, available in various diameters and lengths. The most commonly used sizes are 6, 8, and 10 mm in diameter, with a length of about 3 to 4 cm.

Doweling Works Like This

The "doweling" system (the term used for assembly with wooden dowels) involves drilling holes into the two parts to be joined, where the dowels are then inserted. This allows for a more solid joint with greater resistance to shear and tensile stress.

The main challenge in using this system is the need to drill the holes with a high degree of precision; otherwise, during assembly, the holes won’t align, making the joint impossible.

To assist with this process, there are several kits readily available in specialist shops or online. The most commonly used ones are:

The dowel point kit

The dowel point kit includes dowel points in various sizes, drill bits, and of course, wooden dowels. These kits can be purchased for a single dowel size (6, 8, or 10 mm), or as more comprehensive kits containing components for all three sizes.

The Drilling Guide

Another widely used and user-friendly kit includes a drilling guide. This tool allows you to easily create perpendicular holes centred within the thickness of the wood, and to accurately transfer the drilling points onto both pieces so that they align perfectly during assembly.

This kit also contains the necessary components for doweling in the three most commonly used sizes: 6, 8, and 10 mm.

The Electric Doweling Machine

The fastest and most precise system is the use of a tool specifically designed for this purpose, like the one shown in this photo. However, these tools come with a higher price tag and are typically used by those who require them for professional purposes.

Use Wooden Dowels Without Special Tools

If you need to use wooden dowels but don't have any of the specialised tools, there's an alternative method that's simple, affordable, and not complicated at all.

In this guide, I'll demonstrate how to drill accurate holes for inserting beech dowels for furniture assembly. This is especially helpful when joining two pieces—one edge to another side. The biggest challenge lies in drilling the holes in both pieces precisely enough so they align perfectly.

All you'll need is some masking tape, a pencil, and an awl. Now, let's dive into the steps with some photos:

Doweling with Masking Tape

First, carefully apply masking tape to the back of the piece to be drilled, and use a pencil to trace the edges. This way, when you reposition the tape onto the side of the other piece, there's no room for error.

Positioning the Tape on the First Piece

The tape should be aligned with one side flush to the edge of the wood. Then, from this edge, draw a line that is exactly in the centre of the thickness of the board.

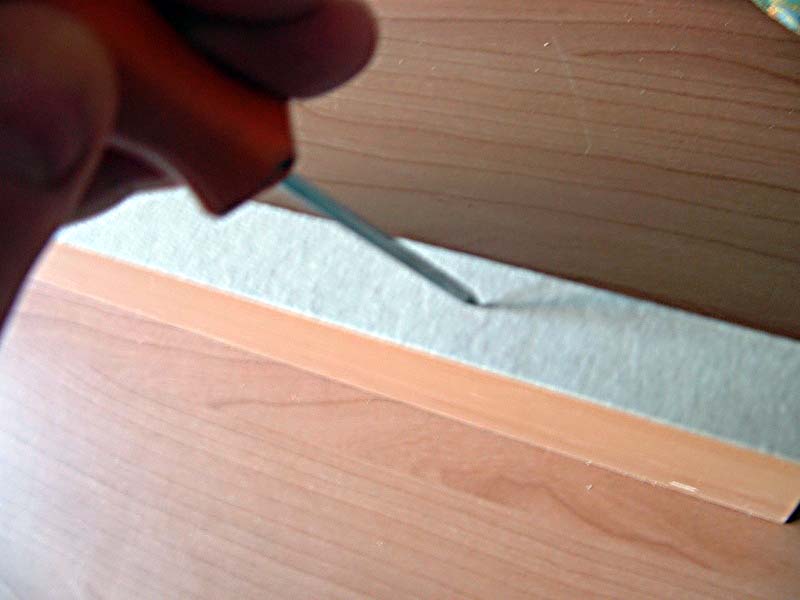

Next, use an awl or a small nail to create holes along the tape, ensuring that the holes are also made in the wood underneath. It's not necessary for the holes to be evenly spaced, as they will be replicated in the exact same positions on the other piece. The important thing is that all the holes are positioned along the line you’ve drawn on the tape.

In this photo, you can see the hole made in the piece.

Positioning the Tape on the Second Piece

Now, remove the tape and reposition it perfectly square with the edge of the side piece, ensuring that the two side marks made with the pencil on the edges of the piece align perfectly. Then, use an awl to mark through the holes previously made.

At this point, all that's left to do is drill the holes and insert the dowels—the two pieces will fit together perfectly. :) It's easier done than said.

If anything is unclear, feel free to ask—you're welcome to do so in the ongoing forum discussion at the following link:

https://www.ilsitodelfaidate.it/FDTForum/viewtopic.php?t=7790

Thank you

Mariobrossh