Indice

- Introduction

- Materials Used

- Difficulty, Time & Cost

- Sliding‑Door Shoe Cabinet (by Mariobrossh)

- Project and Cutting List

- Grooves for the Guides and Tracks

- Housing for the Bottom Carriages and the Spring‑Loaded Top Guides

- Drilling and Installing the Cam‑Lock Fasteners

- Drilling and Installing the Cam Locks

- Dry‑Fit Test of the Back Panel

- Installing the Shelf Supports

- Installing the Inclined Shelves

- Conclusion

Introduction

In this article, I present a new project created by our friend Mariobrossh: a DIY shoe cabinet with sliding doors, built entirely from melamine‑faced chipboard and equipped with a professional sliding system using guides and roller carriages.

It’s a particularly interesting build because it shows, step by step, how to install the sliding guides correctly, how to prepare the grooves, and how to assemble a knock‑down cabinet using dowels, threaded inserts and cam‑lock fasteners.

If you’re looking for a practical and useful project that’s suitable for anyone with a bit of woodworking experience, this guide will walk you through every stage — from the first test cuts to the final installation of the sliding doors.

Materials Used

- White melamine‑faced chipboard panels with visible grain

- Beechwood dowels

- Threaded inserts and cam‑lock fasteners

- Sliding‑door kit consisting of:

- Sliding door tracks

- Bottom roller carriages

- Spring‑loaded top guides

- Plywood or hardboard for the back panel

- Shelf supports

- Recessed handles for sliding doors

Tools Required

- Drill and wood drill bits

- Router with a groove‑cutting bit

- Circular saw or table saw for cutting the panels

- Tape measure, square and pencil

- Clamps

- Screwdriver or cordless driver

Difficulty, Time & Cost

- Difficulty level: Intermediate

- Estimated time: 1–2 days

- Estimated cost: Variable depending on the panels and sliding‑door kit, generally moderate

Sliding‑Door Shoe Cabinet (by Mariobrossh)

Good morning, dear friends.

A new adventure has begun. This time I was asked to build a type of furniture I had never made before: a shoe cabinet with sliding doors.

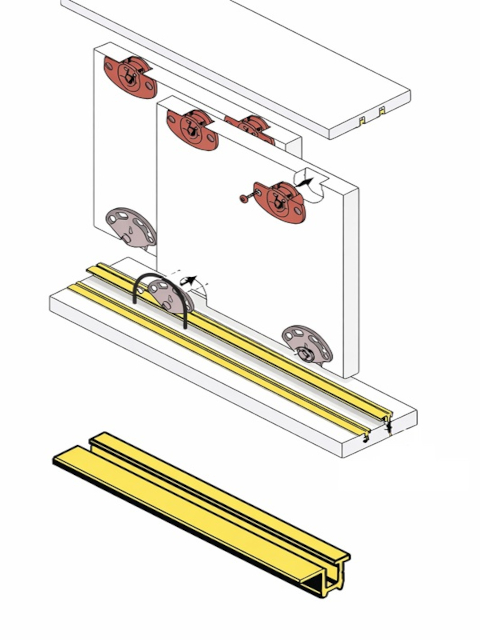

Since I had never installed this kind of system before, the first thing I did was purchase a kit very similar to the one shown in the photo.

The kit includes two bottom roller carriages, two spring‑loaded top guides and, of course, four tracks, one upper and one lower track for each door.

Project and Cutting List

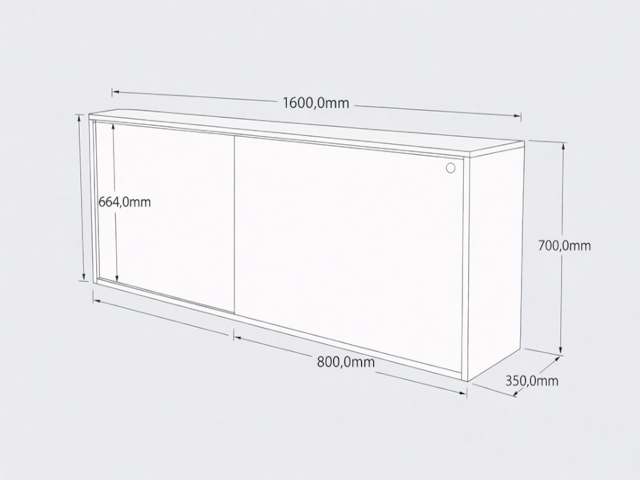

The cabinet is a rectangular unit measuring 180 × 70 × 35 cm, built using white melamine‑faced chipboard with a visible grain pattern.

The assembly is designed to be carried out using wooden dowels and cam‑lock fasteners with threaded inserts.

To organise the work properly, I prepared a drawing from which I could extract the complete cutting list.

Grooves for the Guides and Tracks

After a few tests, I used a handheld router to cut two parallel 8 mm grooves along the top panel of the cabinet, where the upper sliding‑door tracks will be installed.

I then cut another two grooves along the bottom panel, which will house the lower tracks used by the bottom roller carriages.

Next, I pressed the plastic guides into the grooves I had just cut.

These guides will act as the sliding rails for the doors, ensuring smooth and stable movement along the entire length of the cabinet

Housing for the Bottom Carriages and the Spring‑Loaded Top Guides

On each of the two doors, I drilled 30 mm holes to house the bottom roller carriages, and additional holes along the top edge for installing the spring‑loaded upper guides.

The spring mechanism is essential because it allows the guides to retract during the installation or removal of the doors, making the whole mounting process much easier and safer.

Drilling and Installing the Cam‑Lock Fasteners

Since the cabinet needed to be fully demountable, I decided to use cam‑lock fasteners with connecting bolts, which in my opinion are quite easy to install and provide a sufficiently strong clamping force.

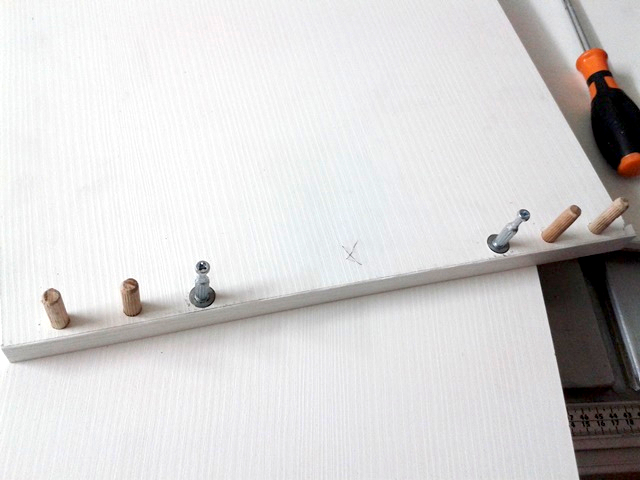

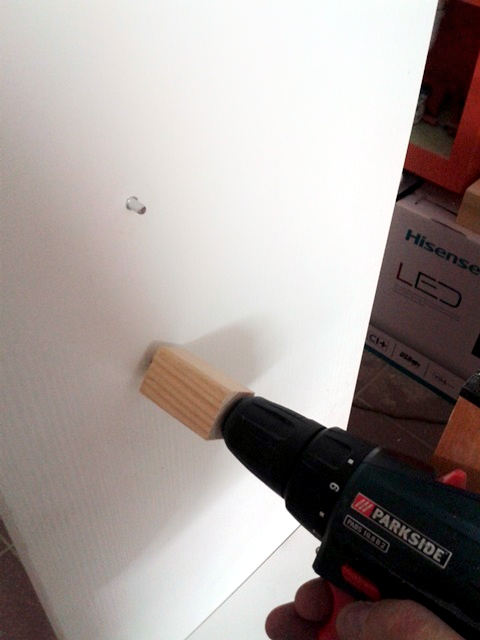

To increase the rigidity of the joints, it’s always good practice to add a few beechwood dowels as well. Without using glue, the dowels give the structure the extra stability it needs while still allowing the cabinet to be taken apart whenever necessary.

For each pair of panels to be joined, I drilled four smaller holes for the beech dowels and two larger holes for the threaded inserts that will receive the cam‑lock bolts.

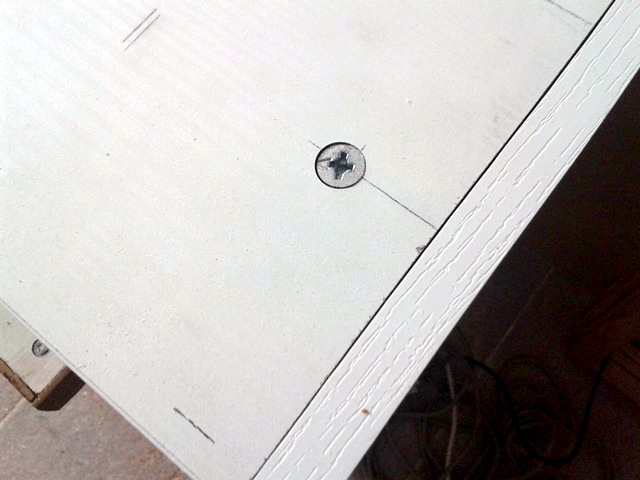

In this photo you can see the threaded inserts screwed into the larger holes.

These inserts are what the cam‑lock bolts will later be screwed into, completing the fastening system and ensuring a solid and reliable joint between the panels

Drilling and Installing the Cam Locks

Normally, when assembling wall cabinets, the top and bottom panels are fitted between the two side panels.

In this case, however, since the cabinet is quite low, using that standard layout would leave the upper joint line between the side panel and the top clearly visible.

For this reason, I preferred to “hide” the top edge of the side panels by placing them under the top panel.

In my opinion, this gives the cabinet a cleaner and more uniform appearance.

Of course, this isn’t a rule — it’s simply a matter of personal preference.

The cam‑lock barrels are installed on the inside of the side panels or, as in this case, on the underside of the bottom panel, so that they remain completely hidden from view once the cabinet is assembled

.

Anyone who would like to explore the techniques for assembling this type of joint in greater depth can refer to this clear and comprehensive article written by our master craftsman, Mariobrossh:

How to Build Furniture Using "Pin and Barrel" Assembly (by Mariobrossh)

Dry‑Fit Test of the Back Panel

I carried out a dry‑fit test to check that the back panel slid correctly into the 4 mm groove.

Since the cabinet is designed to be fully demountable, the back panel will be screwed on rather than inserted from above into a closed groove.

This solution allows me to recover a few extra centimetres of usable space inside the cabinet, which is always welcome in a shoe storage unit.

Installing the Shelf Supports

Once the outer frame of the cabinet was assembled, I installed the brackets for the shelves — the small pin‑type shelf supports.

To mount them correctly, you need to drill holes using a depth‑limited drill bit. This prevents drilling too deep and accidentally coming out on the other side of the panel.

Normally, this is done with a proper depth‑stop collar that clamps onto the drill bit.

Since I didn’t have a dedicated tool at hand, I used a simple homemade solution, which worked just as well.

Installing the Inclined Shelves

Since this cabinet is used as a shoe rack, having the option to install the shelves at an inclined angle offers two advantages:

it gives you a few extra centimetres of usable depth, and it allows the shoes to slide naturally into position without needing to be pushed all the way back.

Conclusion

All that’s missing now are the feet and a few final details, but the cabinet is practically finished.

It’s worth noting that the handles must be recessed handles for sliding doors; otherwise, the handle on the rear door would hit the front door, preventing it from opening fully.

For being my first experience working with sliding doors, I’m quite satisfied with the result: the system runs smoothly, the cabinet is solid, and the interior space is used to its full potential.

I hope you enjoyed this new project by Mariobrossh and that the photos and explanations will be helpful to anyone who wants to try building a cabinet with sliding doors.

As always, my thanks go to all of you who have read the article to the end: your interest is what gives value to the time spent collecting, organising and sharing these projects.

A special thank‑you, of course, goes to Mariobrossh, who with his precision and generosity continues to offer the community useful and well‑crafted work.

If you’d like to explore other woodworking projects similar to this one but on different topics, feel free to browse the Carpentry section of this website.

Thank you once again for your support, and happy woodworking!

Luciano (Capitan Farloc)